Iinkqubo zokupholisa i-nitrogen engamanzi zisetyenziswa kakhulu kwishishini le-semiconductor kunye ne-chip, kuquka nenkqubo,

- Itekhnoloji yeMolecular Beam Epitaxy (MBE)

- Uvavanyo lwetshiphusi emva kwephakheji yeCOB

Iimveliso eziNxulumeneyo

I-EPITAXY YE-MOLECULAR BEAM

Itekhnoloji yeMolecular Beam Epitaxy (MBE) yaphuhliswa ngeminyaka yoo-1950 ukulungiselela izixhobo zefilimu ezincinci ze-semiconductor kusetyenziswa itekhnoloji ye-vacuum evaporation. Ngophuhliso lwetekhnoloji ye-vacuum ephezulu kakhulu, ukusetyenziswa kwetekhnoloji kuye kwandiswa kwicandelo lesayensi ye-semiconductor.

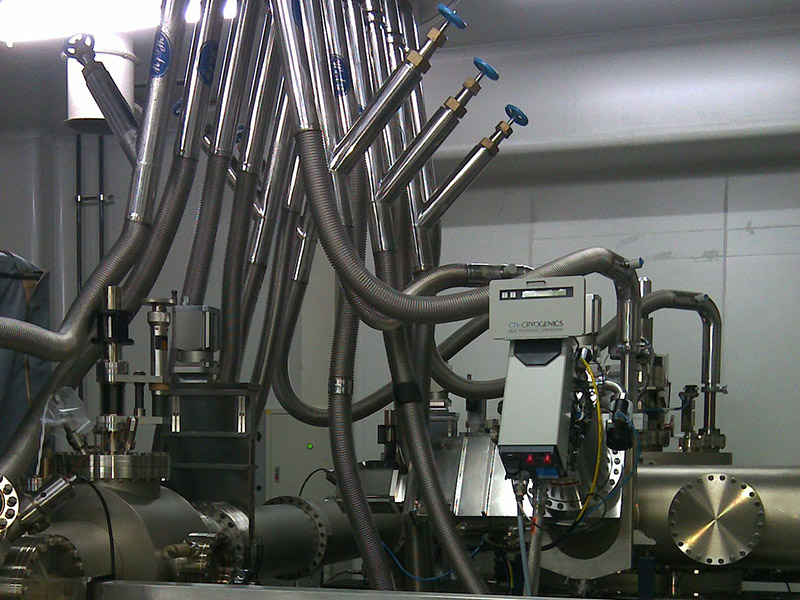

I-HL iqaphele imfuno yenkqubo yokupholisa i-MBE liquid nitrogen, yacwangcisa umqolo wobugcisa ukuze iphuhlise ngempumelelo inkqubo ekhethekileyo yokuphola i-MBE liquid nitrogen yetekhnoloji ye-MBE kunye neseti epheleleyo yenkqubo yokuphola nge-vacuum insulation, esetyenziswa kumashishini amaninzi, kwiiyunivesithi nakumaziko ophando.

Iingxaki eziqhelekileyo kushishino lwe-semiconductor kunye ne-chip ziquka,

- Uxinzelelo lweNitrogen yolwelo kwiZixhobo zeTerminal (MBE). Thintela ukuxinana koxinzelelo kwiZixhobo ezonakalisayo zeTerminal (MBE).

- Ulawulo lwe-Multiple Cryogenic Liquid Inlet kunye ne-Outlet

- Ubushushu beNitrogen yolwelo kwiZixhobo zeTerminal

- Isixa Esifanelekileyo Sokukhutshwa Kwegesi E-Cryogenic

- (Ngokuzenzekelayo) Ukutshintsha kweMigca ephambili neyesebe

- Uhlengahlengiso loxinzelelo (Ukunciphisa) kunye nokuzinza kwe-VIP

- Ukucoca Izinto Ezingcolisayo Nentsalela Yomkhenkce Evela Etankini

- Ixesha lokuzaliswa kwezixhobo zeTerminal Liquid

- Ukupholisa imibhobho ngaphambi kokuba iphole

- Ukumelana nolwelo kwiNkqubo yeVIP

- Ukulawulwa kokulahleka kweNitrogen yolwelo ngexesha lokungasebenzi kakuhle kwenkqubo

I-HL's Vacuum Insulated Pipe (VIP) yakhiwe ngokwekhowudi ye-ASME B31.3 Pressure Piping njengomgangatho. Amava obunjineli kunye nokukwazi ukulawula umgangatho ukuqinisekisa ukusebenza kakuhle kunye nokusebenza kakuhle kwesityalo somthengi.

IZISOMBULULO

Izixhobo ze-HL Cryogenic zibonelela abathengi ngeNkqubo yeMibhobho eVimba iVacuum ukuze bahlangabezane neemfuno neemeko zoshishino lwe-semiconductor kunye ne-chip:

1. Inkqubo yoLawulo loMgangatho: Ikhowudi yeMibhobho yoXinzelelo ye-ASME B31.3.

2.Isihlukanisi seSigaba esiKhethekileyo esineMultiple Cryogenic Liquid Inlet kunye neOutlet enomsebenzi wokulawula ngokuzenzekelayo ihlangabezana neemfuno zokukhutshwa kwegesi, i-nitrogen engamanzi ephinda isetyenziswe kunye nobushushu be-nitrogen engamanzi.

3. Uyilo lokukhupha umoya olwaneleyo nolufike ngexesha luqinisekisa ukuba izixhobo zesiphelo zihlala zisebenza ngaphakathi kwexabiso loxinzelelo oluyilelweyo.

4. I-Gas-liquid Barrier ibekwe kumbhobho we-VI othe nkqo ekupheleni kombhobho we-VI. I-Gas-liquid Barrier isebenzisa umgaqo wokutywina igesi ukuvimba ubushushu ukusuka ekupheleni kombhobho we-VI ukuya kwi-VI Piping, kwaye inciphise ngempumelelo ukulahleka kwe-nitrogen engamanzi ngexesha lenkonzo engaqhubekiyo nengakhawuleziyo yenkqubo.

5. I-VI Piping Elawulwa yiValve efakwe iVacuum Insulated (VIV) Series: Kubandakanya iValve yokuvala iVacuum Insulated (Pneumatic), iValve yokujonga iVacuum Insulated, iValve yokulawula iVacuum Insulated njl. Iintlobo ngeentlobo zeVIV zinokudityaniswa ukuze zilawule iVIP njengoko kufuneka. I-VIV idityaniswe ne-VIP prefabrication kumenzi, ngaphandle konyango lwe-Insulated kwindawo. Iyunithi yesitywina seVIV inokutshintshwa ngokulula. (I-HL iyamkela uphawu lwevalvu ye-cryogenic oluchongiwe ngabathengi, ize emva koko yenze iivalvu ezifakwe ivacuum insulated yi-HL. Ezinye iimpawu kunye neemodeli zeevalvu zisenokungakwazi ukwenziwa zibe ziivalvu ezifakwe ivacuum insulated.)

6. Ucoceko, ukuba kukho iimfuno ezongezelelweyo zokucoceka komphezulu wetyhubhu yangaphakathi. Kucetyiswa ukuba abathengi bakhethe imibhobho yentsimbi engagqwaliyo ye-BA okanye ye-EP njengemibhobho yangaphakathi ye-VIP ukunciphisa ukuchitheka kwentsimbi engagqwaliyo.

7. Isihluzi seVacuum Insulated: Coca ukungcola okunokwenzeka kunye nentsalela yomkhenkce etankini.

8.Emva kweentsuku ezimbalwa okanye ukuvalwa okanye ukulungiswa okude, kuyimfuneko kakhulu ukupholisa izixhobo ze-VI Piping kunye ne-terminal ngaphambi kokuba kufakwe ulwelo lwe-cryogenic, ukuze kuthintelwe ukutyibilika komkhenkce emva kokuba ulwelo lwe-cryogenic lungene ngqo kwi-VI Piping kunye ne-terminal equipment. Umsebenzi wokupholisa ngaphambi kokupholisa kufuneka uqwalaselwe kuyilo. Ubonelela ngokhuseleko olungcono kwizixhobo ze-terminal kunye nezixhobo zenkxaso ze-VI Piping ezifana neevalvu.

9.Ilungele zombini iNkqubo yeMibhobho yeDynamic kunye neStatic Vacuum Insulated (Flexible).

10. Inkqubo yeMibhobho ye-Dynamic Vacuum Insulated (Flexible): Iquka ii-VI Flexible Hoses kunye/okanye i-VI Pipe, ii-Jumper Hoses, i-Vacuum Insulated Valve System, ii-Phase Separators kunye ne-Dynamic Vacuum Pump System (kubandakanya ii-vacuum pumps, ii-solenoid valves kunye nee-vacuum gauges njl.njl.). Ubude be-single VI Flexible Hose bunokwenziwa ngokwezifiso ngokweemfuno zomsebenzisi.

11. Iintlobo ezahlukeneyo zoQhagamshelo: Uhlobo loQhagamshelo lweVacuum Bayonet (VBC) kunye noQhagamshelo oluDibeneyo lunokukhethwa. Uhlobo lweVBC aludingi unyango olugqunywe ngaphakathi kwindawo.