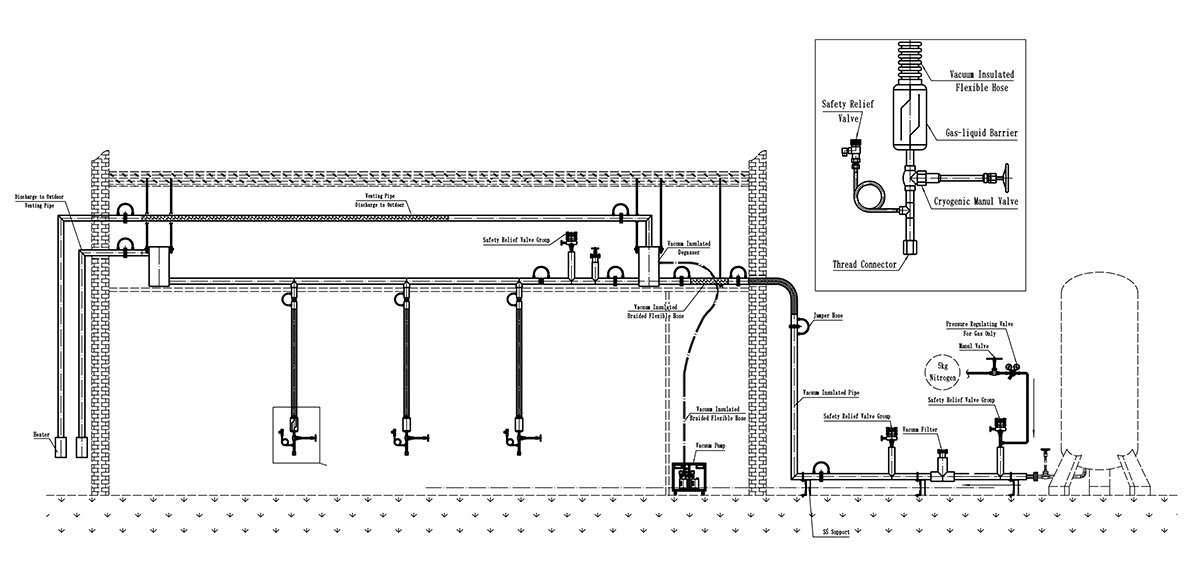

Ukwenziwa kunye noyilo lwe-Vacuum Insulated Piping System yokuhambisa i-nitrogen engamanzi luxanduva lomthengisi. Kule projekthi, ukuba umthengisi akanazo iimeko zokulinganisa kwindawo, kufuneka kubonelelwe ngemizobo yecala lombhobho yindlu. Emva koko umthengisi uza kuyila i-VI Piping System yeemeko ze-nitrogen engamanzi.

Umthengisi uza kugqibezela uyilo olupheleleyo lwenkqubo yemibhobho ngabayili abanamava ngokwemizobo, iiparameter zezixhobo, iimeko zendawo, iimpawu ze-nitrogen engamanzi kunye nezinye izinto ezibonelelwe ngumceli mngeni.

Umxholo woyilo uquka uhlobo lwezixhobo zenkqubo, ukumisela izinto kunye neenkcukacha zemibhobho yangaphakathi neyangaphandle, uyilo lweskimu sokufakelwa kobushushu, iskimu secandelo esele silungisiwe, uhlobo loqhagamshelwano phakathi kwamacandelo emibhobho, isibiyeli semibhobho yangaphakathi, inani kunye nendawo yevalvu yokufunxa, ukususwa kwesitywina segesi, iimfuno zolwelo oluyi-cryogenic kwizixhobo zesiphelo, njl. Le skimu kufuneka iqinisekiswe ngabasebenzi abaziingcali bomceli mngeni ngaphambi kokuba yenziwe.

Umxholo woyilo lwe-Vacuum Insulated Piping System ubanzi, apha kusetyenziso lwe-HASS kunye nezixhobo ze-MBE kwiingxaki eziqhelekileyo, incoko elula.

Ipayipi ye-VI

Itanki yokugcina i-nitrogen engamanzi idla ngokuba yinde ukusuka kwizixhobo ze-HASS Application okanye ze-MBE. Ngelixa umbhobho ogqunywe nge-vacuum ungena kwisakhiwo ngaphakathi, kufuneka uthintelwe ngokusengqiqweni ngokwendlela ebekwe ngayo igumbi kwisakhiwo kunye nendawo yombhobho wasentsimini kunye nombhobho womoya. Ke ngoko, xa kuthuthwa i-nitrogen engamanzi ukuya kwizixhobo, ubuncinane amakhulu eemitha zombhobho.

Ngenxa yokuba i-nitrogen engamanzi ecinezelweyo ngokwayo inegesi eninzi, kunye nomgama wokuhamba, nombhobho we-vacuum adiabatic uya kuvelisa i-nitrogen eninzi kwinkqubo yokuthutha. Ukuba i-nitrogen ayikhutshwa okanye ukukhutshwa kwayo kuphantsi kakhulu ukuba kuhlangatyezwane neemfuno, iya kubangela ukumelana negesi kwaye ikhokelele ekuhambeni kakubi kwe-nitrogen engamanzi, nto leyo ekhokelela ekunciphiseni okukhulu kwesantya sokuhamba.

Ukuba isantya sokuhamba kwamanzi asanele, ubushushu kwigumbi le-nitrogen engamanzi lesixhobo abunakulawulwa, nto leyo enokubangela umonakalo kwisixhobo okanye umgangatho wemveliso.

Ngoko ke, kuyimfuneko ukubala ubungakanani be-nitrogen engamanzi esetyenziswa zizixhobo zesiphelo (i-HASS Application okanye izixhobo ze-MBE). Kwangaxeshanye, iinkcukacha zombhobho zimiselwa ngokobude bombhobho kunye necala lawo.

Ukususela kwitanki yokugcina i-nitrogen engamanzi, ukuba umbhobho ophambili wombhobho/ipayipi egqunywe nge-vacuum yi-DN50 (ububanzi bangaphakathi yi-φ50 mm), umbhobho/ipayipi yesebe layo yi-DN25 (ububanzi bangaphakathi yi-φ25 mm), kwaye umbhobho ophakathi kombhobho wesebe kunye nezixhobo zesiphelo yi-DN15 (ububanzi bangaphakathi yi-φ15 mm). Ezinye izinto ezifakelwa kwinkqubo yepayipi ye-VI, kubandakanya i-Phase Separator, i-Degasser, i-Automatic Gas Vent, i-VI/Cryogenic (Pneumatic) Shut-off Valve, i-VI Pneumatic Flow Regulating Valve, i-VI/Cryogenic Check Valve, i-VI filter, i-Safety Relief Valve, inkqubo yokucoca, kunye ne-Vacuum Pump njl.

Isahluli seSigaba esiKhethekileyo se-MBE

Isahluli ngasinye sesigaba soxinzelelo oluqhelekileyo se-MBE sinemisebenzi elandelayo:

1. Isixhobo sokulawula inqanaba lolwelo kunye nenkqubo yokulawula inqanaba lolwelo oluzenzekelayo, kwaye siboniswa ngokukhawuleza ngebhokisi yokulawula yombane.

2. Umsebenzi wokunciphisa uxinzelelo: indawo yokungena kolwelo lwesahluli ixhotyiswe ngenkqubo yokuncedisa isahluli, eqinisekisa uxinzelelo lwe-nitrogen oluyi-3-4 bar kumbhobho oyintloko. Xa ungena kwiSahluli seSigaba, yehlisa uxinzelelo ngokuthe chu ukuya kwi-≤ 1Bar.

3. Ulawulo lokuhamba kolwelo: inkqubo yokulawula ukufunxa icwangciswe ngaphakathi kwiSigaba sokwaHlukana. Umsebenzi wayo kukulungisa ngokuzenzekelayo ubungakanani bokungenisa ulwelo xa ukusetyenziswa kwe-nitrogen yolwelo kusanda okanye kuncipha. Oku kunenzuzo yokunciphisa ukutshintshatshintsha koxinzelelo okubangelwa kukungena kwe-nitrogen eninzi yolwelo xa ivalvu ye-pneumatic yokungena ivuliwe kwaye kuthintelwe uxinzelelo olugqithisileyo.

4. Umsebenzi we-Buffer, ivolumu esebenzayo ngaphakathi kwesahluli iqinisekisa ukuhamba ngokukhawuleza okukhulu kwesixhobo.

5. Inkqubo yokucoca: ukuhamba komoya kunye nomphunga wamanzi kwindawo yokwahlulahlula ngaphambi kokuba kudlule i-nitrogen engamanzi, kunye nokukhutshwa kwe-nitrogen engamanzi kwindawo yokwahlulahlula emva kokuba kudlule i-nitrogen engamanzi.

6. Umsebenzi wokunceda ngokuziqhelanisa noxinzelelo olugqithisileyo: Izixhobo, xa ziqala ukugqitha kwi-nitrogen engamanzi okanye phantsi kweemeko ezikhethekileyo, zikhokelela ekwandeni kwegesi ye-nitrogen engamanzi, nto leyo ekhokelela ekucinezelekeni ngoko nangoko kwenkqubo yonke. I-Phase Separator yethu ixhotyiswe nge-Safety Relief Valve kunye ne-Safety Relief Valve Group, enokuqinisekisa ngokufanelekileyo uzinzo loxinzelelo kwisihlukanisi kwaye ithintele izixhobo ze-MBE ukuba zonakaliswe luxinzelelo olugqithisileyo.

7. Ibhokisi yokulawula yombane, ukuboniswa kwexesha langempela kwenqanaba lolwelo kunye nexabiso loxinzelelo, inokuseta inqanaba lolwelo kwisihluzi kunye ne-nitrogen yolwelo kubungakanani bobudlelwane bolawulo. Kwangaxeshanye. Kwimeko yongxamiseko, ukubhuleka ngesandla kwesihluzi solwelo lwegesi kwivalvu yokulawula ulwelo, ukuze abasebenzi kunye nezixhobo ziqinisekise ukhuseleko.

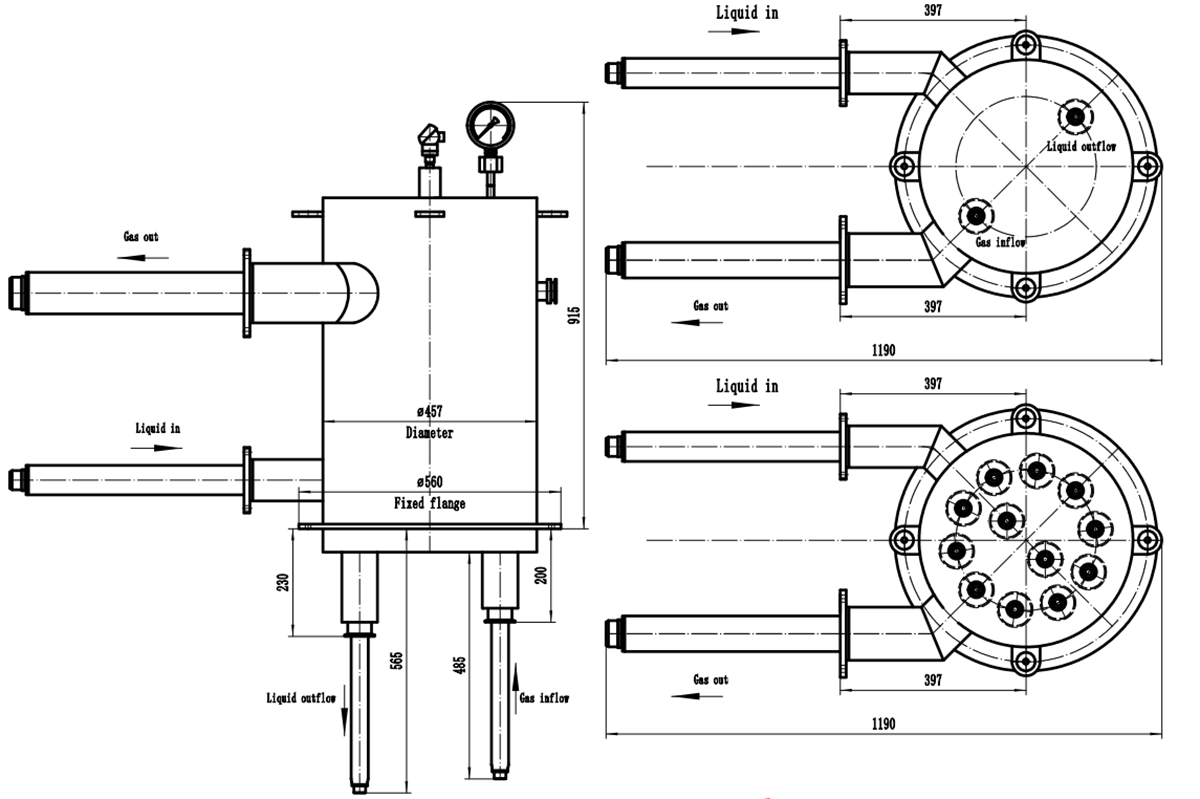

I-Multi-core Degasser yezicelo ze-HASS

Itanki yokugcina i-nitrogen engamanzi yangaphandle ine-nitrogen eninzi kuba igcinwa kwaye ithuthwa phantsi koxinzelelo. Kule nkqubo, umgama wokuhamba ngepayipi mde, kukho iingqiniba ezininzi kunye nokumelana okukhulu, okuya kubangela ukungcoliswa kwe-nitrogen engamanzi kancinci. Ityhubhu egqunywe nge-vacuum yeyona ndlela ilungileyo yokuthutha i-nitrogen engamanzi okwangoku, kodwa ukuvuza kobushushu akunakuphepheka, okuya kukhokelela ekungcolisweni kwe-nitrogen engamanzi kancinci. Ngamafutshane, i-nitrogen engamanzi ine-nitrogen eninzi, ekhokelela ekudalweni kokungangcoliswa kwegesi, okubangela ukuba ukuhamba kwe-nitrogen engamanzi kungagudi.

Izixhobo zokukhupha umoya ezikwipayipi egqunywe nge-vacuum, ukuba akukho sixhobo sokukhupha umoya okanye umthamo wokukhupha umoya owaneleyo, ziya kukhokelela ekuxhathiseni igesi. Nje ukuba ukuxhathisa igesi kwenziwe, amandla okuhambisa i-nitrogen engamanzi aya kuncipha kakhulu.

I-Multi-core Degasser eyilwe yinkampani yethu kuphela inokuqinisekisa ukuba i-nitrogen ikhutshwa kumbhobho we-nitrogen oyintloko yolwelo kangangoko kwaye ithintele ukwakheka kokumelana negesi. Kwaye i-Multi-core Degasser inomthamo owaneleyo wangaphakathi, inokudlala indima yetanki yokugcina i-buffer, kwaye inokuhlangabezana ngempumelelo neemfuno zombhobho wesisombululo okhawulezayo ophezulu.

Ulwakhiwo olukhethekileyo olune-multicore enelungelo elilodwa lomenzi, umthamo wokukhupha umoya osebenza kakuhle kunezinye iintlobo zethu zokwahlulahlula.

Ukuqhubeka nenqaku elingaphambili, kukho imiba ethile ekufuneka iqwalaselwe xa kuqulunqwa izisombululo zeNkqubo yeMibhobho efakwe iVacuum kwizicelo ze-cryogenic kwiShishini leeChip.

Iintlobo ezimbini zeNkqubo yeMibhobho eVimbayo yeVacuum

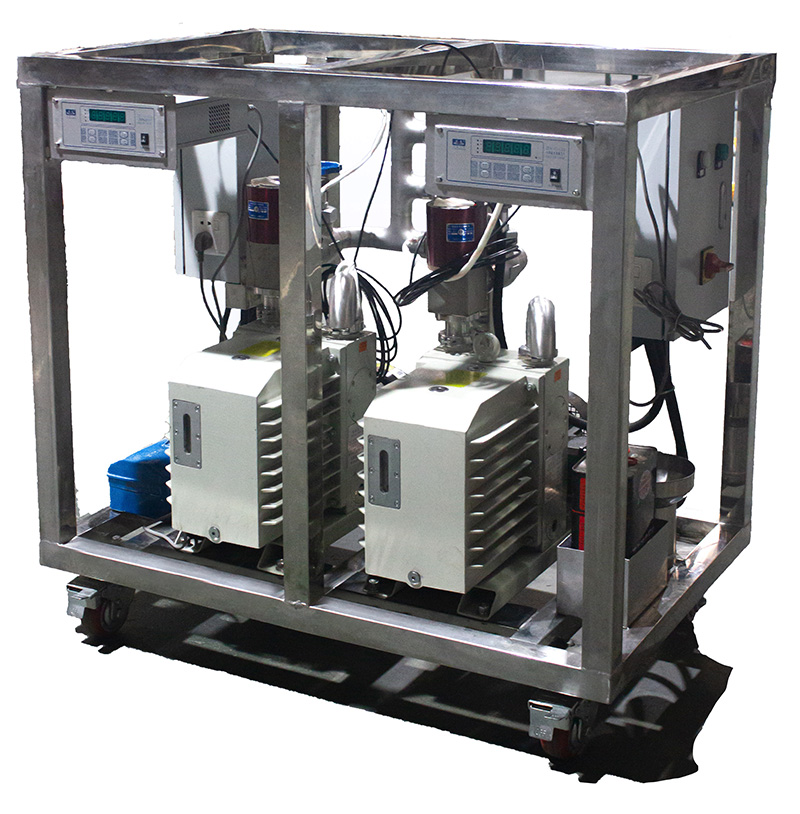

Kukho iintlobo ezimbini zeNkqubo yeMibhobho eVimba iVacuum Insulated: Inkqubo yeStatic VI kunye neNkqubo yeDynamic Vacuum Pumping.

Inkqubo ye-Static VI ithetha ukuba emva kokuba umbhobho ngamnye wenziwe efektri, ucocwa nge-vacuum ukuya kwinqanaba elithile le-vacuum kwiyunithi yokupompa kwaye uvalwe. Xa kufakelwa kwaye kusetyenziswe, ixesha elithile akufuneki liphinde likhutshwe liye kwindawo leyo.

Inzuzo yeStatic VI System ziindleko zokulungisa eziphantsi. Nje ukuba inkqubo yokuhambisa imibhobho isebenze, kufuneka ulondolozo emva kweminyaka eliqela. Le nkqubo yokucoca ifanele iinkqubo ezingadingi mfuneko yokupholisa ephezulu kunye neendawo ezivulekileyo zokulungisa kwindawo leyo.

Ingxaki yeStatic VI System kukuba i-vacuum iyancipha ngokuhamba kwexesha. Ngenxa yokuba zonke izinto zikhupha iigesi ezilandelelanayo ngalo lonke ixesha, nto leyo emiselwa ziimpawu zomzimba zezinto. Izinto ezikwijakethi ye-VI Pipe zinokunciphisa ubungakanani begesi ekhutshwa yinkqubo, kodwa azinakwahlulwa ngokupheleleyo. Oku kuya kukhokelela ekubeni i-vacuum yendawo ye-vacuum evaliweyo ingabi nkulu, kwaye izakuba sezantsi nangaphantsi, ityhubhu ye-vacuum insulation iya kunciphisa kancinci amandla okupholisa.

Inkqubo yokuPompa iVacuum eDynamic ithetha ukuba emva kokuba umbhobho wenziwe kwaye wenziwe, umbhobho usakhutshwa kumzi-mveliso ngokwenkqubo yokufumanisa ukuvuza, kodwa ivacuum ayivalwanga ngaphambi kokuba ihanjiswe. Emva kokuba kugqityiwe ukufakwa kwentsimi, ii-vacuum interlayers zazo zonke iipayipi ziya kudityaniswa kwiyunithi enye okanye ezingaphezulu ngeepayipi zentsimbi engagqwaliyo, kwaye ipompo encinci yevacuum enikezelweyo iya kusetyenziselwa ukucoca imibhobho entsimini. Ipompo ekhethekileyo yevacuum inenkqubo ezenzekelayo yokujonga ivacuum nangaliphi na ixesha, kunye nokucoca njengoko kufuneka. Inkqubo isebenza iiyure ezingama-24 ngosuku.

Ingxaki yeDynamic Vacuum Pumping System kukuba i-vacuum kufuneka igcinwe ngumbane.

Inzuzo yeDynamic Vacuum Pumping System kukuba i-vacuum degree izinzile kakhulu. Isetyenziswa kakhulu kwindawo yangaphakathi kunye neemfuno zokusebenza kwe-vacuum kwiiprojekthi eziphezulu kakhulu.

Inkqubo yethu yokuPompa iVacuum eDynamic, yonke ipompo ekhethekileyo ye-vacuum edibeneyo yeselula ukuqinisekisa ukuba izixhobo ziyasuswa, uyilo olulula nolufanelekileyo ukuqinisekisa isiphumo se-vacuum, umgangatho wezixhobo ze-vacuum ukuqinisekisa umgangatho we-vacuum.

Kwiprojekthi ye-MBE, kuba izixhobo zikwigumbi elicocekileyo, kwaye izixhobo zisebenza ixesha elide. Uninzi lwenkqubo yemibhobho egqunywe nge-vacuum ikwindawo evaliweyo kumaleko wegumbi elicocekileyo. Akunakwenzeka ukuphumeza ukugcinwa kwe-vacuum kwenkqubo yemibhobho kwixesha elizayo. Oku kuya kuba nefuthe elibi ekusebenzeni kwenkqubo ixesha elide. Ngenxa yoko, iprojekthi ye-MBE isebenzisa phantse yonke iNkqubo yokuPompa i-Dynamic Vacuum.

Inkqubo yoNcedo loxinzelelo

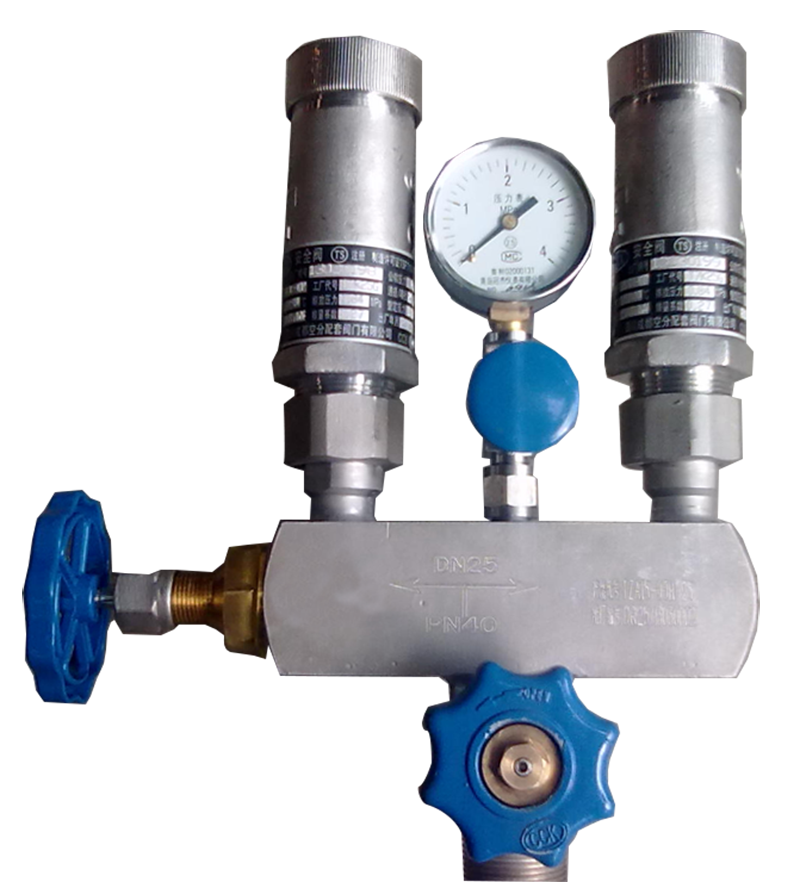

Inkqubo yokunciphisa uxinzelelo yomgca oyintloko isebenzisa iSafety Relief Valve Group. ISafety Relief Valve Group isetyenziswa njengenkqubo yokukhusela ukhuseleko xa uxinzelelo olugqithisileyo, iipayipi ze-VI zingenakulungiswa xa zisetyenziswa ngendlela eqhelekileyo.

Ivalvu yoKhuseleko loKhuseleko yinxalenye ebalulekileyo yokuqinisekisa ukuba inkqubo yepayipi ayizukucinezelwa kakhulu, ayizukuba nokusebenza ngokukhuselekileyo, ngoko ke ibalulekile ekusebenzeni kwepayipi. Kodwa ivalvu yokhuseleko ngokwemigaqo, kufuneka ithunyelwe ukuze ihlolwe rhoqo ngonyaka. Xa kusetyenziswa ivalvu yokhuseleko enye kwaye enye ilungisiwe, xa ivalvu yokhuseleko enye isusiwe, enye ivalvu yokhuseleko isekwinkqubo yepayipi ukuqinisekisa ukusebenza okuqhelekileyo kwepayipi.

Iqela le-Safety Relief Valve liqulathe ii-DN15 Safety Relief Valves ezimbini, enye yokusetyenziswa kunye nenye yokulinda. Kwindlela eqhelekileyo yokusebenza, inye kuphela ii-Safety Relief Valves ezidityaniswe ne-VI Piping System kwaye zisebenza ngendlela eqhelekileyo. Ezinye ii-Safety Relief Valves ziqhagamshelwe kumbhobho wangaphakathi kwaye zingatshintshwa nangaliphi na ixesha. Ii-safety valves ezimbini ziqhagamshelwe kwaye zinqunyulwe ngendlela yokutshintsha i-valve esecaleni.

Iqela leSafety Relief Valve lixhotyiswe ngegeyiji yoxinzelelo ukujonga uxinzelelo lwenkqubo yemibhobho nangaliphi na ixesha.

Iqela leValve yoKhuseleko libonelelwe ngevalvu yokukhupha umoya. Ingasetyenziselwa ukukhupha umoya kumbhobho xa ihlanjwa, kwaye i-nitrogen ingakhutshwa xa inkqubo ye-nitrogen engamanzi isebenza.

Izixhobo ze-HL Cryogenic

I-HL Cryogenic Equipment eyasekwa ngo-1992 luphawu oludityaniswe neChengdu Holy Cryogenic Equipment Company eTshayina. I-HL Cryogenic Equipment izibophelele kuyilo nasekwenziweni kweHigh Vacuum Insulated Cryogenic Piping System kunye nezixhobo zenkxaso ezinxulumene noko.

Kwihlabathi lanamhlanje elitshintsha ngokukhawuleza, ukubonelela ngetekhnoloji ephucukileyo ngelixa ukonga iindleko kubathengi ngumsebenzi onzima. Kangangeminyaka engama-30, i-HL Cryogenic Equipment Company phantse kuzo zonke izixhobo ze-cryogenic kunye namashishini inomdla onzulu kwisicelo, iqokelele amava atyebileyo kwaye inokuthenjwa, kwaye iyaqhubeka nokuhlola kwaye izama ukuhambisana nophuhliso lwamva nje kuzo zonke iindlela zobomi, inika abathengi izisombululo ezintsha, ezisebenzayo nezisebenzayo, yenze abathengi bethu bakhuphisane ngakumbi kwimarike.

For more information, please visit the official website www.hlcryo.com, or email to info@cdholy.com .

Ixesha lokuthumela: Agasti-25-2021